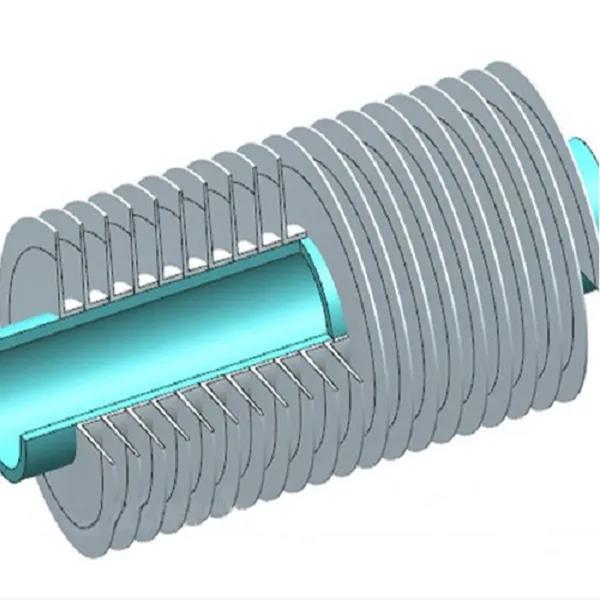

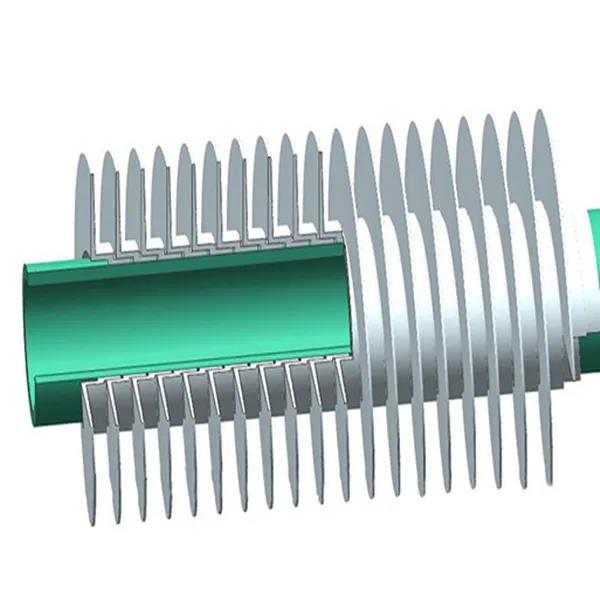

The L FIN TUBE, LL FIN TUBE, KL FIN TUBE also known as Winding FinTube.This type of fin tube widely finds acceptance where the heat transfer temperature is relatively lower and the cost needs to be controlled. These fintubes are relatively lesser in cost as compared to the ‘G’Type Fin Tube and the Extruded Type Fin Tube . |

Specification

Tube OD | 19~51 (mm) |

Tube Wall Thk | 1.65~3.0(mm) |

Tube Length | ≤18,500 (mm) |

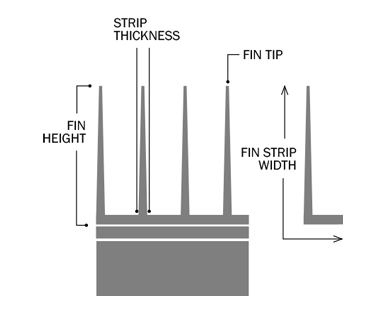

Fin Thk | 0.3~0.5 (mm) |

Fin Height | 10~16 (mm) |

Fin Pitch | 100~433 FPM |

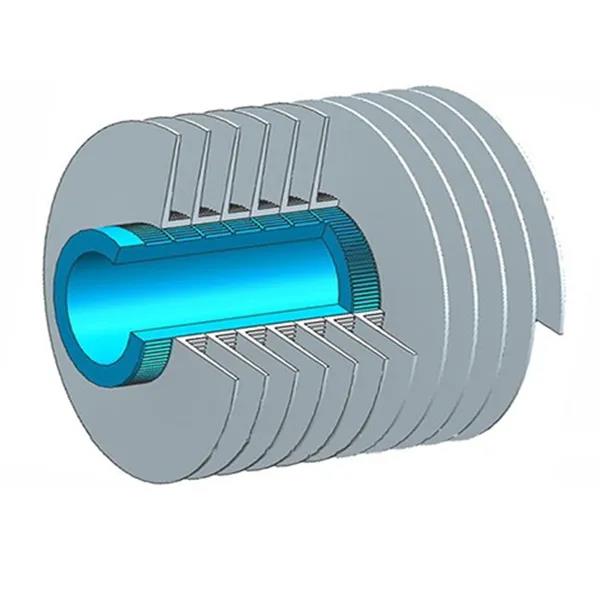

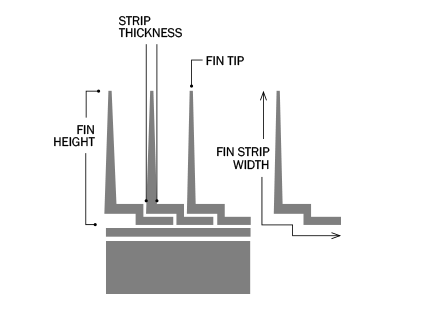

L-Type

In ‘L’ Type Fin Tube or also known as ‘L’ Foot Fin Tube, the finning is done by wrapping around the Fin stock spirally around the base tube. This is as reason also known as spirally wound FinTube.The base of the fin stock is shaped in to and ‘L’ shape which gives a base for the fin to stand on firmly. Also the ‘L’ shape provides a certain protection against the atmospheric corrosion. |

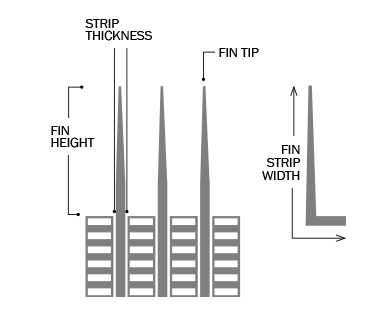

LL-Type

LL type winding finned tube: under the l-type foundation, the fin root completely covers the outer surface of the base tube, which can strengthen the contact surface and increase the heat exchange effect. Maximum operating temperature: 170℃. Doule "L" fin is used on applications requiring additional corrosion protection to the surface of the base tube. The protection process is similar to the L Fin Tube type. However, the improvement is that the "L" Foot of the previous fin is completely over lapped by the "L" Foot of the next fin. This gives the Fin base a shape of tow "L" foot simultaneously. Operating temperature is a little high than for L fin. A wide range of both tube and fin materials are available. Heat transfer performance canbe enchaned by utilising unique internal solder or pulled in secondary surface / turbulator system. |

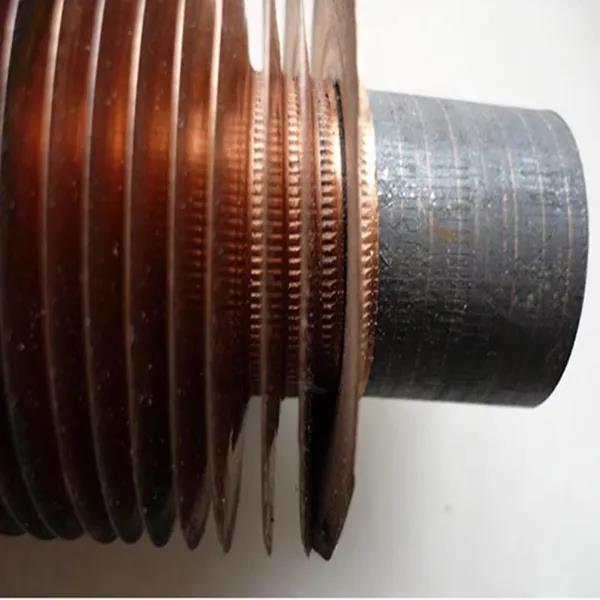

KL-Type

KL type finned tube is also known as knurled finned tube. It is used to roll the pattern on the base tube before winding the fin, or to add a blade on the winding machine. Knurling is used on the base tube, and the blade behind is used for winding. Before the fins are continuously wound on the surface of the steel pipe, the outer surface of the base pipe needs to undergo a knurling process; after the fins are wound, the root of the fin attached to the steel pipe will also be knurled to strengthen the steel pipe and Combination of fins. For this reason, this fin type ensures better heat transfer characteristics under the fins of L and LL. Commonly used heat sink materials are aluminum and copper. |