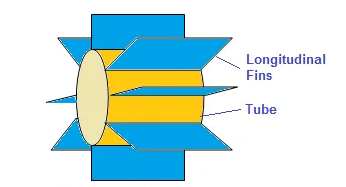

Longitudinal finned tubes are produced by welding the fins with resistance along the length of the tube. The fins first form a u-shaped channel, allowing each of the u-shaped legs to form a fin. The channel is cut to the appropriate length and then welded into place along the length of the tube and resistance. The channels are a pair of welded, polar opposites, so the number of fins specified must be a multiple of four. For a given tube or tube size, the desired heat transfer surface area per tube unit length can be obtained by specifying the appropriate fin height and number of fins.The maximum number of fins depends on the outer diameter of the tube - the larger OD tube can accommodate more fins. |

Product Parameters of Longitudinal Fin Tube

Tube O.D.: | 12~273 (mm) |

Tube Wall Thk.: | 2.11~25.4(mm) |

Tube Length: | ≤12000 (mm) |

Fin Thk.: | 1.0~1.5 (mm) |

Fin Height: | 5~25 (mm) |

Fin Qty: | 1U~36U |

Fin Type: | “U" |

Product characteristics * Improve heat transfer efficiency in efficient space. * Reduces installation space on required heat transfer surfaces * Reduce the cost of the equipment, and have a high operational reliability. * The pressure drop on the side of the tube is reduced and the operation cost is reduced. * The stiffness of steel tube is improved, and the seismic performance of steel tube is improved. * Enhance heat transfer, reduce flow resistance and metal consumption Competitive Advantage 1. Longer working life than others ordinary welding helical fin tubes. 2. Much safer and energy saving. 3. Increase the heat transfer rates for viscous liquids. 4. Perforated fin type used whenever drainage of liquid from fin channels become a problem. 5. Longitudinal fin tubes are widely used in horizontal heat exchangers.

Applications The longitudinal finned tubes are widely used in following fields. 1. Chemical, petrochemical, oil, and power industry 2. Heat exchanges 3. Fired heaters 4. Gas coolers and heaters 5. Tank heaters. |