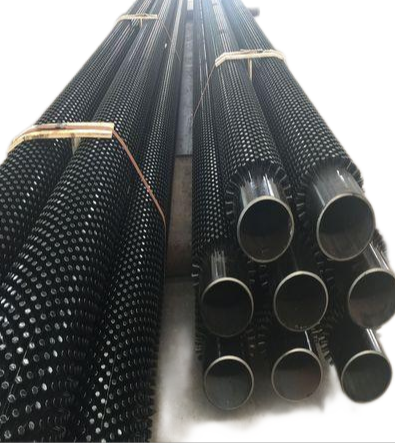

The steel studs are automatically resistance welded to the tube, producing high quality forge welds. The welding process enables the combination of any grades for studs and tube: carbon, low alloy, stainless steels and high nickel alloys. Alloy steel pipes are stress-relieved after studding, according to the relevant specifications for the class and grade of steel used. |

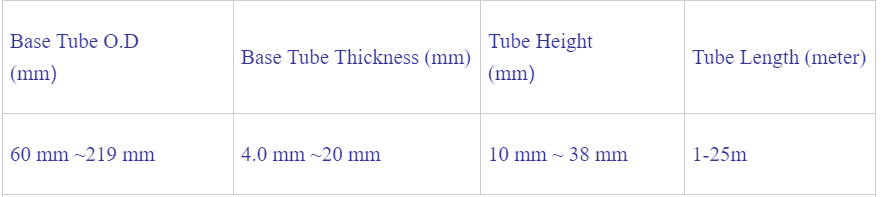

Specification of studded tube

| The studs are attached to the pipe in diametrically opposing pairs around the circumference by electrical resistance welding to ensure a high integrity bond for strength and heat flow. Stud diameter, height and pitch can be specified on an individual basis. |

Product Advantages * Increase efficiency in the process of heat recovery and direct flame hostile atmospheres * Reduce the amount of bare pipes used in these processes. (Heat transfer surface of one studded pipe is equivalent to surface of 4 to 10 bare pipes) * Ideal for processes applications where dirty fuels are used and harsh environments in terms of temperature and corrosion |