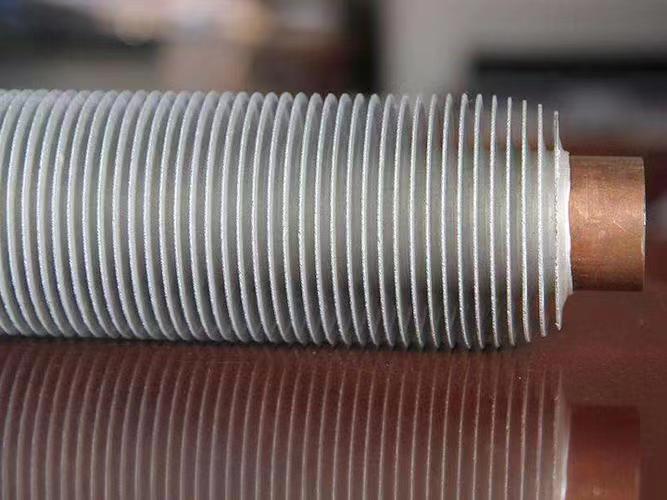

The extruded fin tubes are categorized into extruded single metal fin tube and extruded bimetallic fin tube.

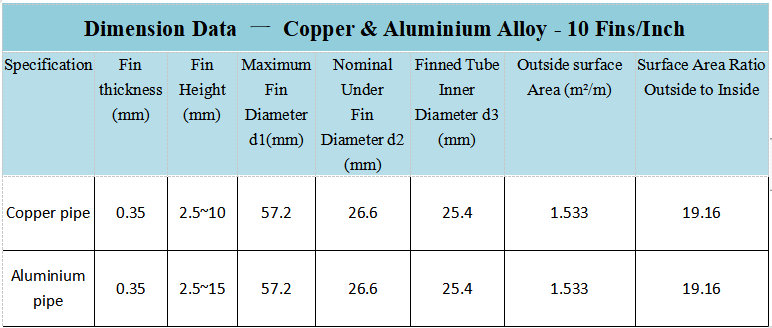

Specifications

Tube Material | Stainless Steel, Copper, Carbon steel, Alloy |

Tube OD | 10-57mm |

Tube Wall Thickness | 1.0mm-4.0mm |

Fin Material | Aluminum, copper |

Fin OD | 25~82mm |

Fin thickness | 0.2~1mm |

Fin Pitch | 1.8~8mm |

Fin Height | less than 18mm |

The fin tube can be finished as bent pipe, coils, and ocher custom design shapes.

| Extruded Single Metal Fin Tube |

| Extruded single metal fin tube is made of single metal, such as aluminum fin tube or copper fin tube, stainless steel fin tube and so on. This kind of fin tube has no contact heat resistance,high strength,heat shock resistance and mechanical vibration resistance, good thermal expansion performance, and has a considerable extended heat transfer surface. |

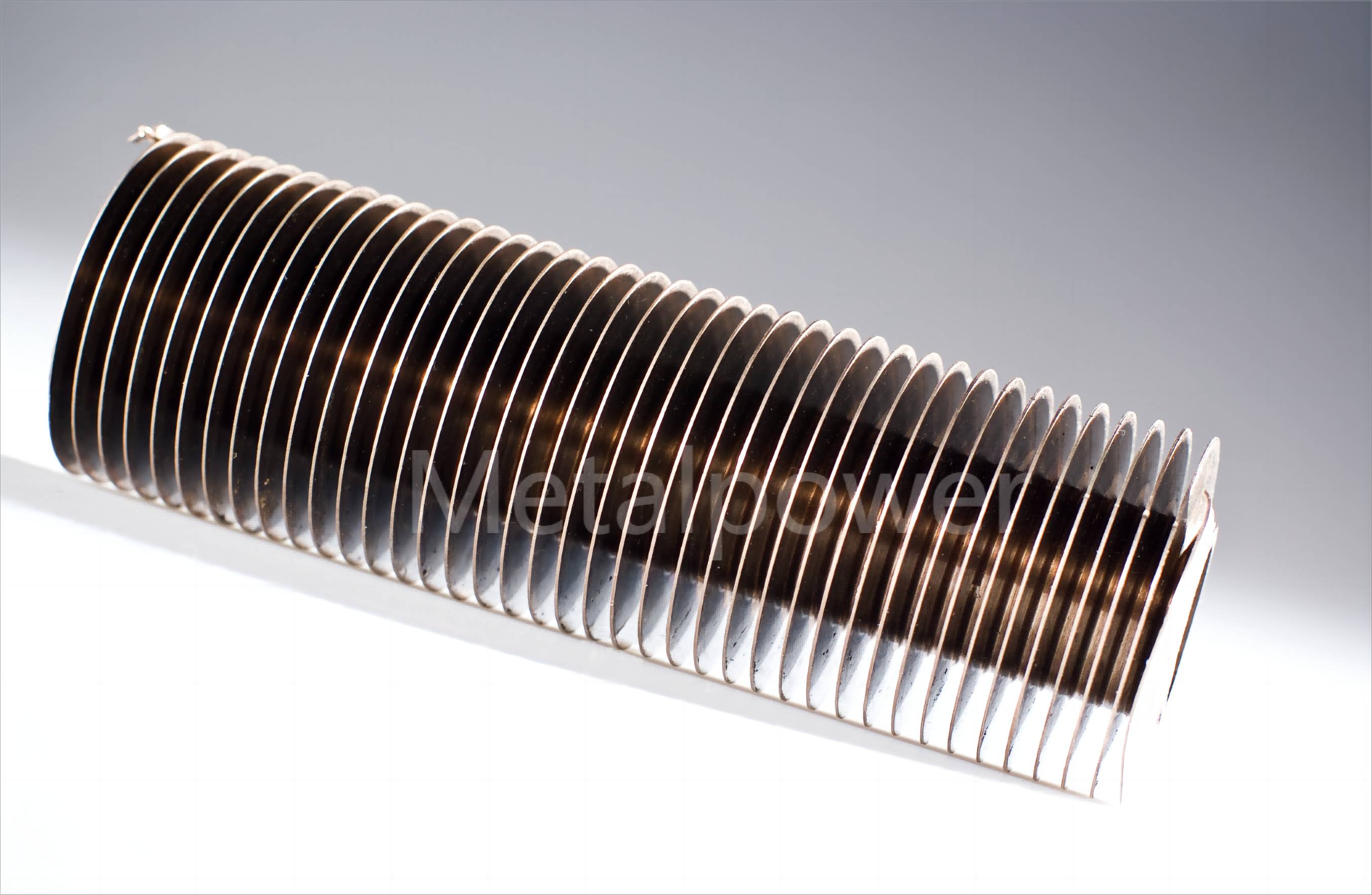

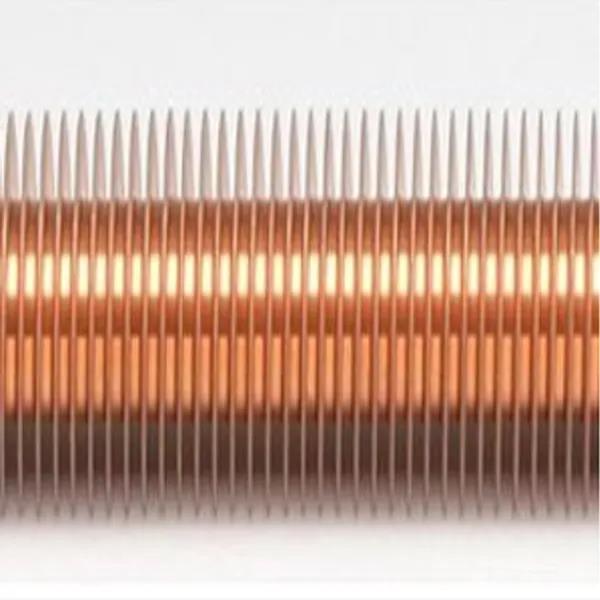

| 1. Copper Fin Tube |

Copper finned tube is a heat transfer element. In order to improve the heat transfer efficiency, usually add fins to the surface of the heat exchange tube to increase the surface area ( or internal surface area ) of the heat exchang tube, so as to achieve the purpose of improving the heat transfer efficiency. The overall fin tube has no contact thermal resistance, it has good heat transfer performance, high strength, thermal vibration and mechanical vibration resistance, good thermal expansion performance. Whole rolled fin is smooth without burr, no wrinkle, easy to clean, in the heat exchange heating and other occasions not easy to dust, fouling. |

Manufacturing process Pipe line——compressing or rolling——strip peeling——washing——pressure test——blast blowing——packaging. The cold machining process of fins provides excellent mechanical resistance, fins are strong and have strong atmospheric corrosion resistance, etc.The pressure required to extrude fin from the copper sleeve creates an excellent “pressure bond” between the two materials. Application Typically extruded fins are uesd in corrosive atmospheric conditions, such as off-shore allpications, widely applied in equipment like water cooler, air cooler, heat exchenger, boiler and burners and so on. |

| 2. Aluminum Fin Tube |

Typically extruded fins are uesd in corrosive atmospheric conditions,such as off-shore allpications, it also widely applied in equipment like water cooler, air cooler,heat exchenger,boiler and burners and so on. Single metal composite fin tube is made of aluminum tube by the whole rolling, called aluminum rolled fin tube, no contact termal resistance, high strength, heat resistance and mechanical vibration, thermal expansion performance is good, and has a considerable expansion of heat transfer surface. Whole rolled fin is smooth without burr, no wrinkle, easy to clean, in the heating and air conditioning engineering wet cooling is easy to remove the condensation on the outside surface of the fin, in the heat exchange heating and other occasions not easy to dust, fouling. |

| Quality Assurance |

| 1. Compliance with quality standards, ASME SB111, SB-359, SA-213, SA-450 and all codes as per ASME /EN/ JS. |

| 2. Customer / Third Party Inspection TPI. |

| 3. Stress relief annealing of non-ferrous fin tube on in-house electric conveyor belt furnace. |

| 4. Stress relief annealing of ferrous fin tubes as per specifications provided if required by client at additional cost. |

| 5. 100% tubes tested for leakages by hydrostatic Test as per standard and customers requirements. |

| Applications |

| *HVAC & Boiler |

| * Power Plants |

| * Heat Recovery Steam Generators |

| * Petrochemical Industries |

| * Marine Applications |

| * Refrigeration Applications |

| * Economizers |

| * Oil and Gas Coolers |

| * Plumbing and Air Conditioning |

| * Condensers and Evaporators |

| * Other various Heat Exchanger Applications |

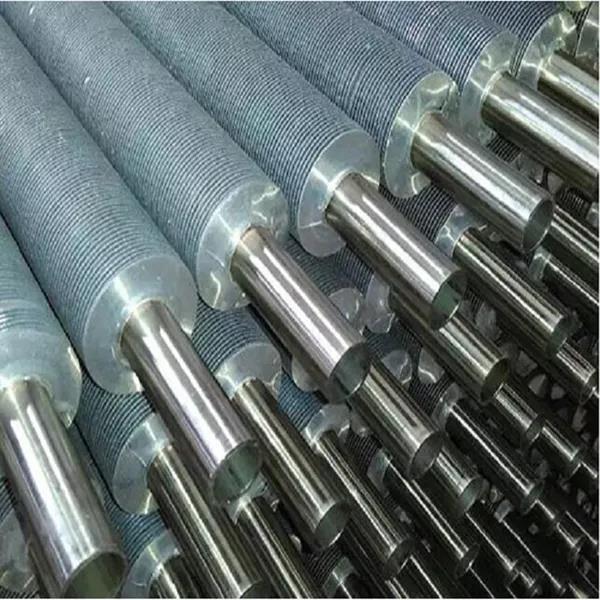

Extruded Bimetallic Fin Tube Extruded bimetallic fin tube is two kinds of metal composite and then rolled fin,such as copper and aluminum fin tube, steel and aluminum fin tube, copper and steel composite fin tube and so on. It features compact design, small thermal resistance, good heat transfer performance, strong corrosion resistance, not easy to deformation under long-term cold and hot condition, long working life and so on. |

If you want to know more demension datas, please contact us.

1. Copper-Aluminum Fin Tube Copper-aluminum fin tube is a copper-aluminum composite tube that is rolled out of fins after compounding.It has characteristics of close combination, small thermal resistance, good heat transfer performance, high strength, small flow loss, strong corrosion resistance. It is not easy to be deformed in the case of long-term cold and hot work and long working life. Whole rolled fin is smooth without burr, no wrinkle,easy to clean,in the heating and air conditioning engineering wet cooling is easy to remove the condensation on the outside surface of the fin,in the heat exchange heating and other occasion not easy to dust, fouling. |

2. Steel-Aluminum Finned Tube The processing technology of cold rolled finned tube of steel and aluminum is made from aluminum tube and steel tube into bimetallic tube, and then the finned tube is formed after the mechanical cold rolled tube. Based on the physical characteristics of aluminum tube, the tube with steel tube as the core is made into a finned tube which is closely combined with the cold rolled aluminum fin. |

| Bimetallic Finned Tubes Features |

| ● To improve the heat transfer efficiency in the effective space. |

| ● To Reduce the required installation space for the required heat transfer surfaces. |

| ● To lower equipment cost while having higher operational reliability. |

| ● The running cost is lowered due to lower tube side pressure drop. |

| ● The rigidity of tube is increased, which improves the seismic resistance of the tube. |

● Enhancement of heat transfer, reduction on flow resistance and metal consumption. It is widely used in steel, petroleum, chemical, machinery, shipbuilding, power station, hospital and food industries. |