High frequency welding spiral fin tube is a new kind of heat transfer material which has the feature of wearing resistance and high efficient. Also, it is a kind of high efficiency and energy saving heat transfer element. Widely used in waste heat recovery, petrochemical industry, power plant boiler, economizer, coaches, civil building heating, refrigerating, drying, medicine of wood drying, food drying system and other industries. |

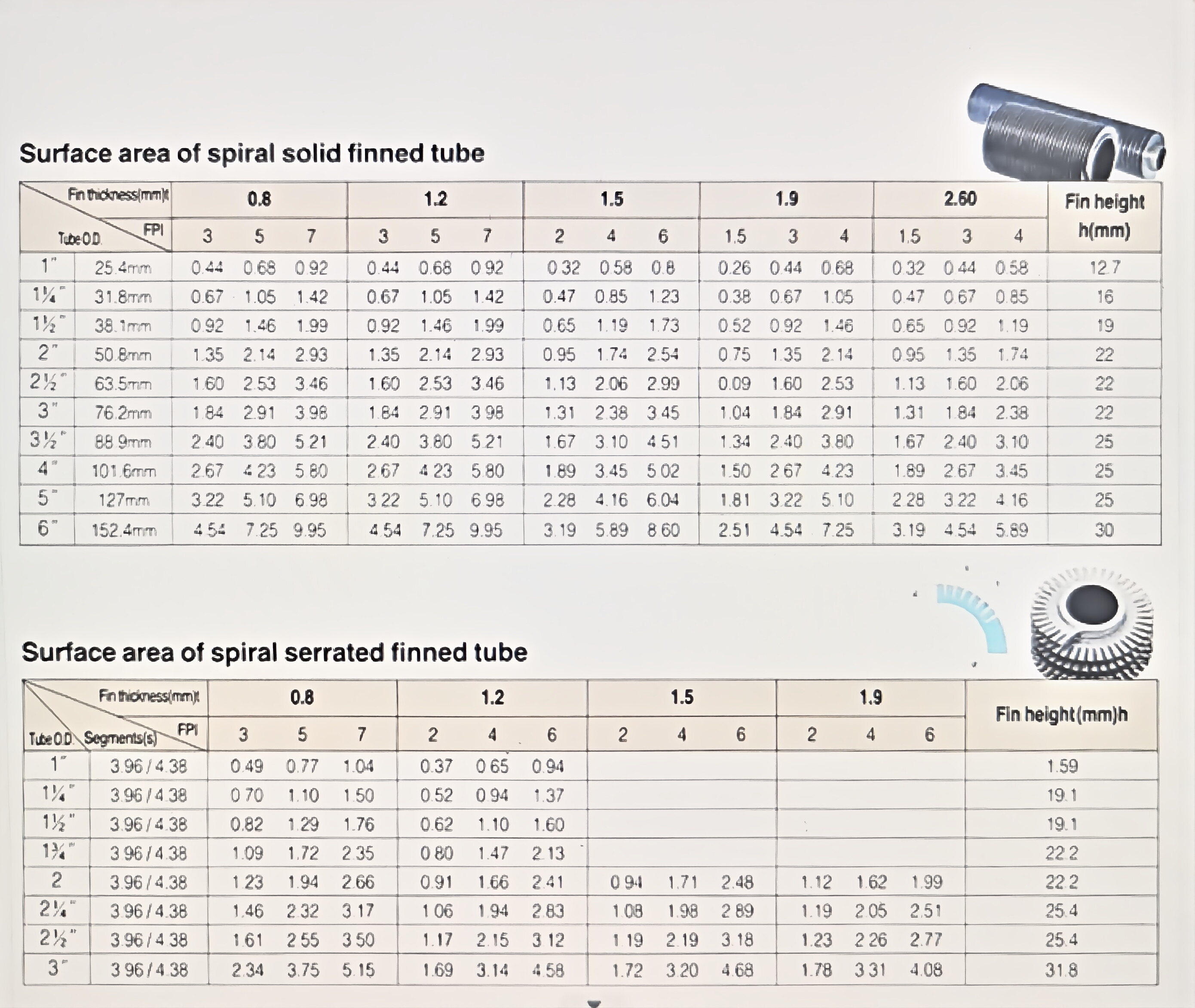

Product Range ●Tube outside diameter :3/8inch~8inch ●Fin thickness :0.8mm~3.2mm ●Fin height :9mm~38mm ●Fin pitch :6OFPM~315FPM ●Finning length :24,000mm( Max .) ●Material : Carbon steel , Low alloy steel , High grade corrosion resistant alloy steel , Ferritic and austenitic stainless steel & Non - ferrous metal . |

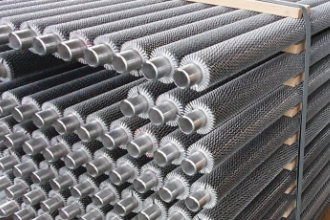

- Solid Type - Serrated Type

The advantages of high frequency welding spiral fin tube: 1. The maximum length of high frequency welding spiral finned tube can reach 6 meters, that reduces the join points, making the installation more economic, efficient, and also reduces the leakage probability of joints. 2. After installation, high frequency welding spiral fin tube needs no longer to be maintained. 3. The heat dissipation area of high frequency welding spiral fin tube is more than 8 times of the light tube.The internal is very smooth, so the internal flow resistance is small. 4. Fin and pipes with high mechanical strength, so the tensile strength is more than 200 mpa. Both inside and outside of the tube are all made of hot dip galvanized processing. |

The advantages of high frequency welding serrated fin tube: 1. Higher heat transfer coefficient. The serrate can make the gas flow across the fins freely, enhancing the turbulent motion and improving the heat transfer effect.Researches show that serrated fintube’s heat transfer efficiency is about15-20% higher than common solid fin tube. 2. Reduce metal consume. Due to the higher heat transfer coefficient, for the same amount of heat, serrated fin tube is with less heat transfer areas, which help reduce the metal consume. 3. Anti-ash-deposition and anti-scaling.Due to the serrate,it's very hard for the serrated fintube to deposit the ash and scaling. 4. It is more flexible to adapt to the changes of gas flow direction. |