| Technique |

| State Of The Art Manufacturing Capability |

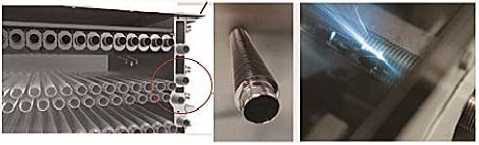

| * German made high power Laser welding system |

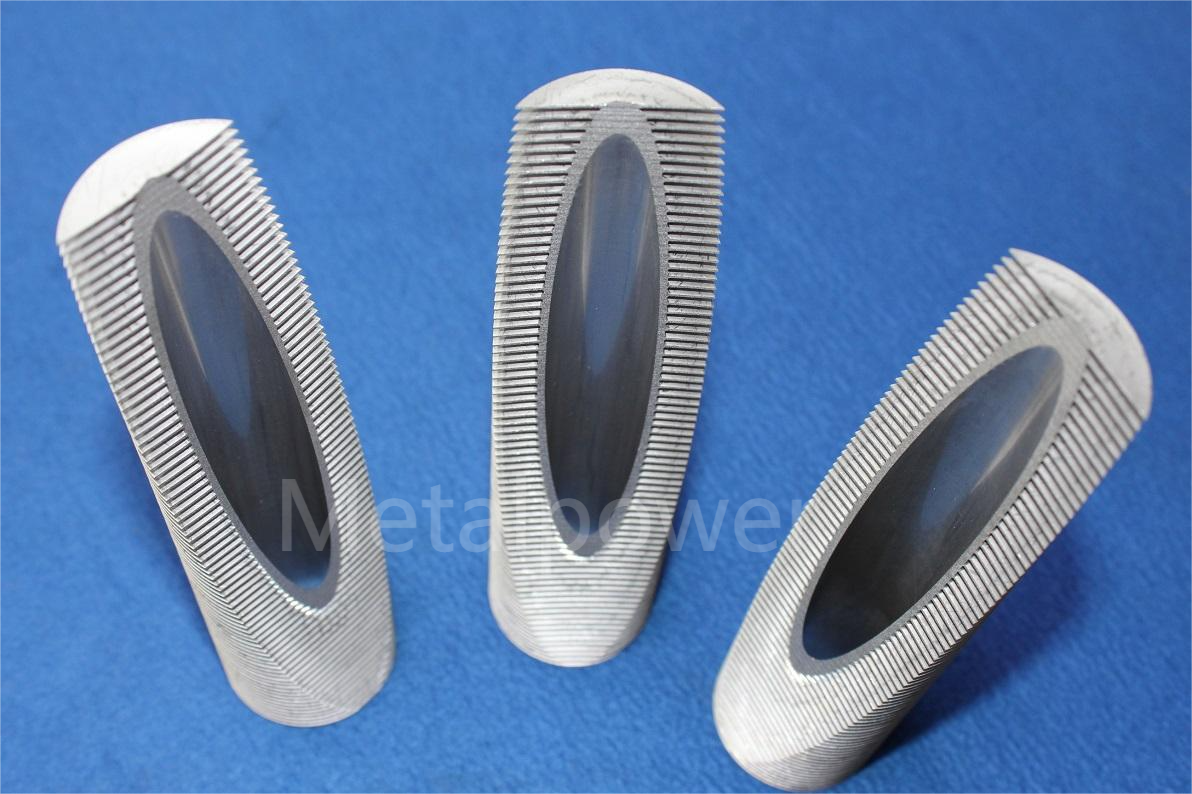

| * Laser welding fin onto tube without filler material |

| * Thin and coninuous weld seam |

| * Laser welding under potective atmosphere |

| * Patented fin winding technology |

Materials & Specifications

Material combinations:

Tube | Stripe |

Stainless steel | Stainless steel |

Stainless steel | Aluminum |

Stainless steel | Copper |

Carbon steel | Carbon steel |

Carbon steel | Aluminum |

Copper nickel | Aluminum |

Copper nickel | Copper |

Titanium | Titanium |

Titanium | Copper |

Dimensions:

Tube outside diameter | 8.0-84.0mm |

Fin outside diameter | 15.00-125.00mm |

Fin pitch | 3-14fin/inch |

Fin height | 4.0mm-17.00mm |

Fin thickness | 0.3mm-1.0mm |

Maximum tube lengths | 12m |

Metallographic Analysis

Poor Laser Welding

Perfect Laser Welding

| The advantages of laser welding: |

| (1) The heat inflow can be reduced to the minimum demand, the range of gold phase change in the thermal influence area is small, and the deformation caused by heat conduction is also the lowest. |

| (2) The welding process parameters of 32mm plate thickness have been verified, which can reduce the time required by thick plate welding and even save the use of filler metal. |

| (3) No need to use electrodes, no concern about electrode contamination or damage. And because it does not belong to the contact welding process, the consumption and deformation of the machine can be minimized. |

| (4) The laser beam is easy to focus, align and guided by the optical instrument, can be placed at an appropriate distance from the workpiece, and can be guided between the tools or obstacles around the workpiece. Other welding rules cannot be played due to the above space limitations. |

| (5) The workpiece can be placed in a closed space (under vacuum or internal gas environment under control). |

| (6) The laser beam can be focused in a very small area and can weld small and closely spaced components. |

| (7) Weldable materials have a wide range of types, but also can be connected to various heterogeneous materials. |

| (8) Easy to automatic high-speed welding, can also be digital or computer control. |

| (9) welding thin material or thin diameter wire, not like arc welding. |

| (10) Not affected by the magnetic field (arc welding and electron beam welding is easy), can accurately align the welds. |

| (11) Two metals of different properties (such as different resistances) can be welded. |

| (12) There is no vacuum required, and no X-ray protection is required. |

| (13) If the welding is perforated, the depth and width ratio of the weld tunnel can reach 10:1. |

| (14) The device can be switched to transmit the laser beam to multiple workstations. |

| Product Advantage |

| * Longer cycle time for maintenance |

| * 100% welding penetration between fin and tube |

| * Strong resisyance to hazard environment if stainless or titanium material applied |

Product Range

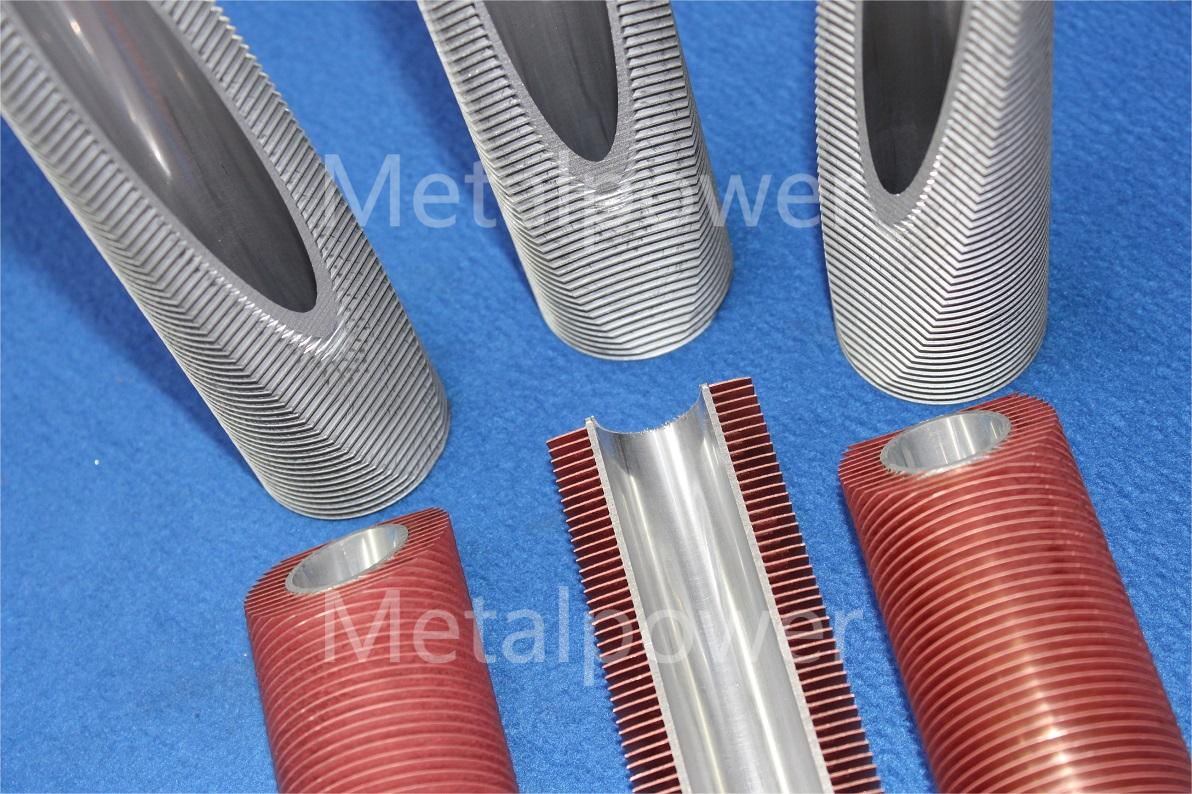

Stainless Steal Laser Welded Fin Tube Straight Tube

| Advantages: high heat transfer efficiency, strong corrosion resistance, and strong welding seam. |

| The fin can be made with different shapes. These fin tubes can be used on condensing heating system. |

| Common materials: 316L, 304,904L, etc. |

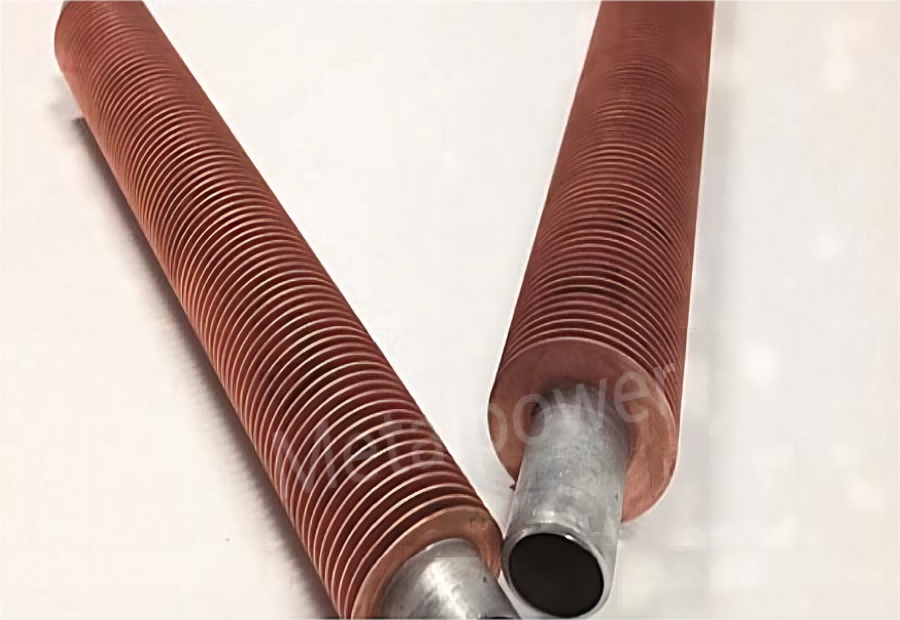

Laser Welded Fin Tube

Laser can weld different metal, such as copper nickel, aluminum, titanium, and carbon steel materials.

Stainless Steal Laser Welded Fin Tube

| Advantages: compact design, high heat transfer efficiency, strong corrosion resistance, etc. |

| These fin tube coils can be used on high-end condensing wall-hanging furnace. |

| Common materials: 316L, 444,904L, etc. |

Stainless Steal Laser Welded Fin Tube Plate Replacement

| Advantages: compact design, high heat transfer efficiency, strong corrosion resistance, etc. |

| These fin tube plate replacements can be used on large gas output and high pressure steam generator. It can solve the common problems of low pressure resistance effectively and easy water leakage. |

| Common materials: 316L, 444,904L, etc. |

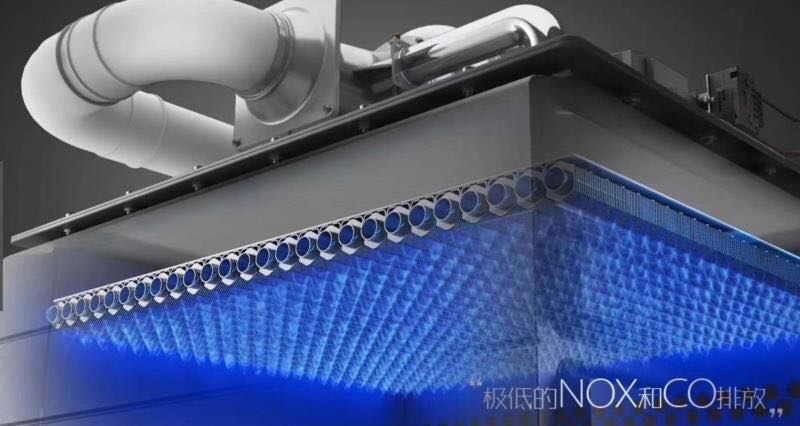

| Industrial Application |

| *Primary heat exchanger in steam gas boiler |

| *Main heat exchanger in domestic condensing hot wather |

| *Petro & Chemical Industry |

| *Applied in cooling and heating for gas and liquid |

| *Heat Recovery Plants |

| *Flume Recovery system |