High frequency welding spiral solid fin tube is manufactured by helically wrapping continuous fin strip on tube. HF Resistance Welding Usually Employs Frequency Of 400 kHz. The fin wound around the tube and continuous weld. The fin strip is wounded spirally onto the tube and welded continuously with a high frequency electrical process to the base tube along the spiral root. The fin strip held under tension and confined laterally as it is formed around the tube, thereby ensuring that the strip is in forceful contact with the base tube surface.

High frequency welding spiral serrated fin tube is now more and more popular in the manufacturing of boiler, pressure vessel and other heat exchanger equipment. Spiral serrated finned tube, serrated fins cut from metal strip and then helically wound around the tubes. Others are same as high frequency welded solid finned Tubes Pipes. The important features of this configuration are efficiency, effective bond of fins to tubes under all conditions of temperature and pressure, and ability to withstand high fin side temperatures. This serrated fin configuration is even better to withstand the fin fouling if that is a problem in the application. This gives better heat transfer properties compared to solid fin.

The advantages of high frequency welding serrated fin tube:

1. Higher heat transfer coefficient. The serrate can make the gas flow across the fins freely, enhancing the turbulent motion and improving the heat transfer effect. Researches show that serrated fin tube’s heat transfer efficiency is about 15-20% higher than common solid fin tube.

2. Reduce metal consume. Due to the higher heat transfer coefficient, for the same amount of heat, serrated fin tube is with less heat transfer areas, which help reduce the metal consume.

3. Anti-ash-deposition and anti-scaling. Due to the serrate, it is very hard for the serrated fin tube to deposit the ash and scaling.

4. It is more flexible to adapt to the changes of gas flow direction.

High frequency welding spiral fin tube is the most widely used of the spiral finned tube, widely used in electric power, metallurgy, cement industry preheating collection and petrochemical industries. High-frequency spiral finned tube is welded steel strip coil pipe at the same time, using high-frequency currents of the skin effect and proximity effect of steel tube, and surface heat until melted in the plastic state or steel strip coil, the complete welding under certain pressure.

The advantages of high frequency welding spiral fin tube:

1. The simple and economic installation

The maximum length of high frequency welding spiral finned tube can reach 6 meters, that reduces the join points, making the installation more economic, efficient, and also reduces the leakage probability of joints.

2. Easy maintenance

After installation, high frequency welding spiral fin tube needs no longer to be maintained.

3. High efficiency

The heat dissipation area of high frequency welding spiral fin tube is more than 8 times of the light tube.The internal is smooth, so the internal flow resistance is small.

4. Long service life

Fin and pipes with high mechanical strength, so the tensile strength is more than 200 mpa. Both inside and outside of the tube are all made of hot dip galvanized processing.

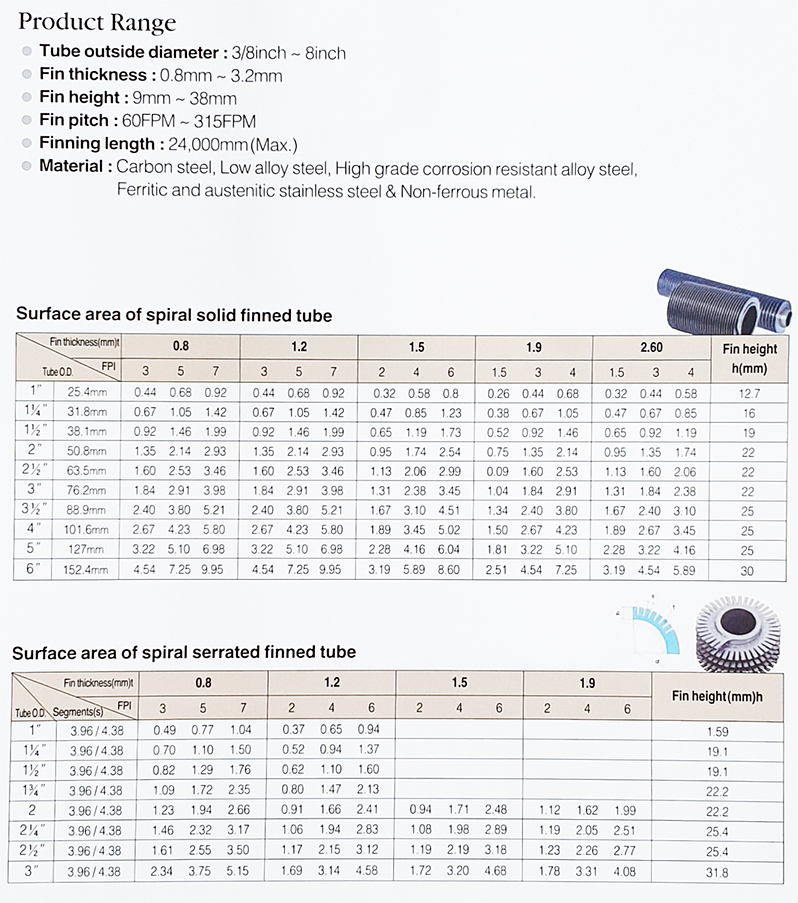

- Solid Type - Serrated Type