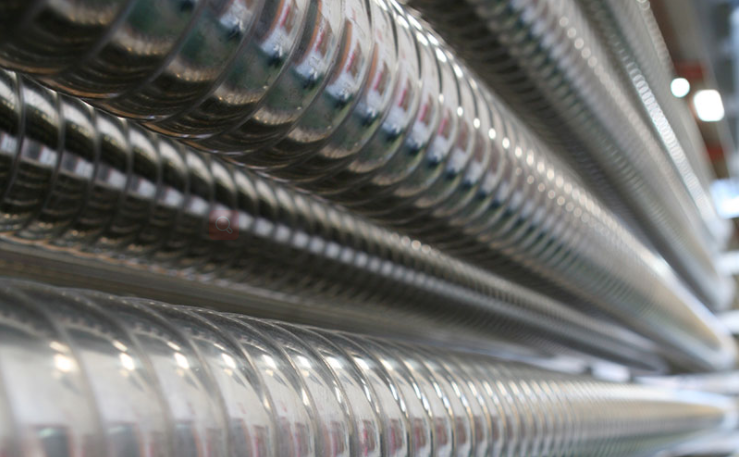

Corrugated tube heat exchangers gives high heat transfer coefficient compared to shell & tube heat exchangers because of increased turbulence in tubes. This reduces heat transfer area for same process duty by almost 40 to 50% which in turn reduces overall capital investment. Hence use of Corrugated Tube Heat Exchanger is most economical solution for any process applications like condensation of vapours, cooling or heating. Corrugated tube is produced by indenting a plain tube with a spiral pattern. No tube wall thinning takes place & no strength is lost.

When used in heat exchangers, corrugated tubes deliver a number of benefits

Corrugated tube heat exchangers have many benefits and advantages over comparable smooth tube versions:

Compact tubular heat exchanger

Long running times due to turbulent flow

Very low maintenance costs, minimum spares requirement

Higher heat transfer coefficient (2-3 times) results in reduction in heat exchanger area up to 50%

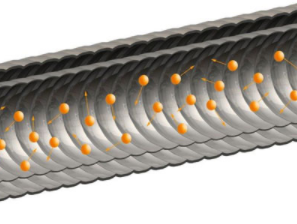

Fouling is minimised due to turbulence created by eddies at the periphery or tube wall

Uniform thermal processing

More flexibility in annular space sizing.

One advantage of corrugated tubes is that they prevent viscous fluids and suspensions from forming an insulating boundary layer on the tube surface.

For some types of viscous material, a corrugated tube provides sufficient turbulence to prevent the need for mechanical agitation, such as in a scraped-surface or screw-driven heat exchanger. With no moving parts, a corrugated tube is much easier to clean and maintain, and may be more reliable, than a scraped-surface heat exchanger, although there are applications where a scraped surface heat exchanger is the better option.